Printed electronics are currently receiving a lot of attention. They promise to develop fields of applications for electronics that were previously not or only partially accessible to conventional electronics. New developments in printed electronics are emerging, for example, in applications such as radio-frequency identification (RFID), displays, and solar cells. However, they also allow the reduction of manufacturing costs or to print on large-areas and flexible substrates.

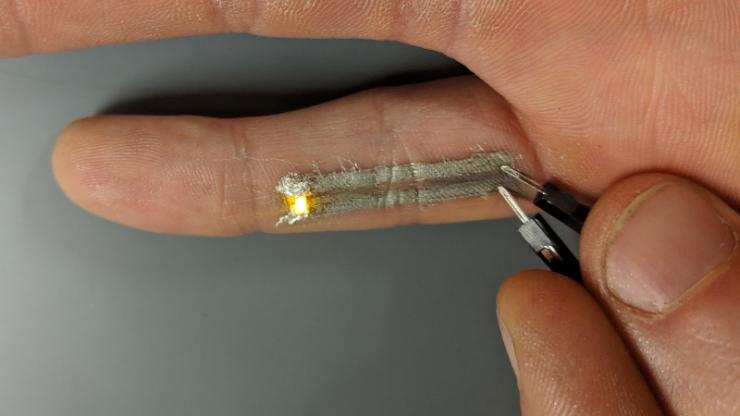

Now, electrical engineers at Duke University have devised a gentle print-in-place technique for electronics to work on delicate surfaces including paper and even human skin. Print-in-place technology means that the sample does not have to be taken out of the printer for processing steps in between, as is the case with other printing electronics processes.

COLLECTION OF ELECTRONIC INKS

“To directly print functional electronics without any processing outside of the printer, we had to overcome challenges related to intermixing between layers, removal of organics without high temperatures, and aerosol jet printing of two-dimensional hexagonal boron nitride into an insulating thin film,” said Aaron Franklin, associate professor at Duke. With this technology, high-adhesion, embedded electronic tattoos are feasible as well as less exotic ideas like bandages with patient-specific biosensors. The thin film sticks to skin like a temporary tattoo. The flexible electronics were made to contain heart and brain activity monitors and muscle stimulators.

In a first study, Franklin’s lab and the laboratory of Benjamin Wiley developed a novel ink containing silver nanowires that can be printed onto any substrate at low temperatures with an aerosol printer. Recently, Franklin took the conductive ink in a second study and combined it with two other printable components to create functional transistors. “The result of our findings is a collection of inks, from semiconducting to metallic to insulating, that are cross-compatible so as to be printed to form custom-designed electronic devices and circuits,” Franklin said.