General Electric (GE) introduced a new water treatment technology for the offshore oil and gas industry. Under the brand name ZeeWeed* 700B horizontal-designed, inside-out ultrafiltration (UF) membrane offers seawater pretreatment for injection and solids removal in offshore oil and gas applications.

Fiber technology and blended polyethersulphone (PES) allow the membrane to stay permanently hydrophilic and reduce the fouling tendency. Polysulfones are thermoplastic polymers known for their toughness and stability. When compared to granular filter media and cartridge filters, it produces superior water quality and is virtually unaffected by variable raw water quality, according to General Electric.

It extends the life of a sulfate removal unit by providing improved pretreatment technology, decreased life cycle costs and reduced weight as well as footprint. In cases where the membranes are used purely for solids removal, it also offers superior reservoir protection.

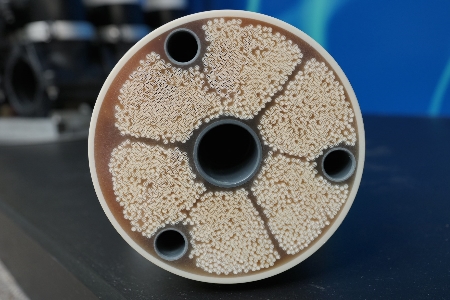

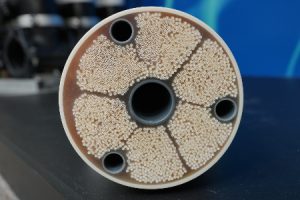

As the company reported, the new membrane uses multibore fibers that are stronger than single bore fibers, and minimizes maintenance and repairs. It does not require air scouring and eliminates the need for blowers. Furthermore the UF technology is supposed to be energy efficient, operating at a lower transmembrane pressure with lower energy requirements.

“The offshore oil and gas industry has strict requirements for materials of construction, space and weight, and GE’s ultrafiltration skids equipped with the new ZeeWeed 700B UF membrane meet these demanding specifications,” said Kevin Cassidy, global leader of engineered systems, water and process technologies for GE Power.

The US company pledges the ZeeWeed technology to be an advanced filtration technology that separates particles, bacteria and viruses from water or wastewater. Nearly 1,000 plants worldwide use this technology. Its ability to handle large volumes of water in a small footprint, combined with the highly efficient process with low energy and low chemical usage, makes it ideal for treating raw water sources like seawater and producing high quality process water for the oil and gas industry.